The SLM3D printer offers a high-performance 3D printing solution for creating precise and functionally robust metal parts with complex geometries. Its remarkable features include high-quality surface finishes pre-polishing, exceptional accuracy for precision samples, and direct production of functional metal parts, streamlining the manufacturing process. The resulting parts exhibit metallurgy and mechanical properties with a relative density exceeding 99%, eliminating the need for additional post-processing. The printer boasts fast print times, ranging from minutes to hours, depending on size and complexity, and is adept at crafting intricate components like snap-fit connectors and loose joint hinges. With a wide array of material options, including single metals and alloys, the SLM3D printer is particularly suited for single-piece or small-batch functional part production, offering an efficient and versatile manufacturing solution to meet various needs.

| LASER SYSTEM | Type:Fiber laser × 2 Wavelength:1064nm Power:500W × 2 |

| RECOATING SYSTEM | Process:Bi-directional Scraper Paving Normal Build:0.05mm Quick Build:0.05~0.15mm Precision Build:0.02~0.05mm |

| OPTICAL & SCANNING | Beam (diameter@1/e²):0.06~0.20mm Scanning Galvanometer:High Speed Scanning Galvanometer × 2 Parts Scanning Speed:4.0m/s (recommended) Blank Jumping Speed:10.0~28.0m/s (recommended) Reference Building Speed:15~60cm³/h |

| SHIELD SYSTEM | Protective gas:N2 / Ar(Active metal materials must be protected with Ar) Flow Control:0~3 L/min intellient adjustment Dust extraction control:High efficiency Protection recycling system |

| BUILD VAT | Volume:Approx. 160L XY Platform:500mm(X) × 400mm(Y) (Screw hole, rounded, etc. are not calculated) Z Axis:900mm(Including substrate thickness) Max Weight:300kg Type:Precision resistor heater Material:Stainless Steel / Die Steel / Titanium Alloy / Aluminium Alloy / Co-Cr Alloy / Nickel Alloy / Cuprum etc. |

| SOFTWARE | Network:Ethernet, TCP/IP, IEEE802.3 Control Software:iSLM(Presto SLM) Date Preparation Software:3dLayer Data Interface:CLI file, SLC file, STL file |

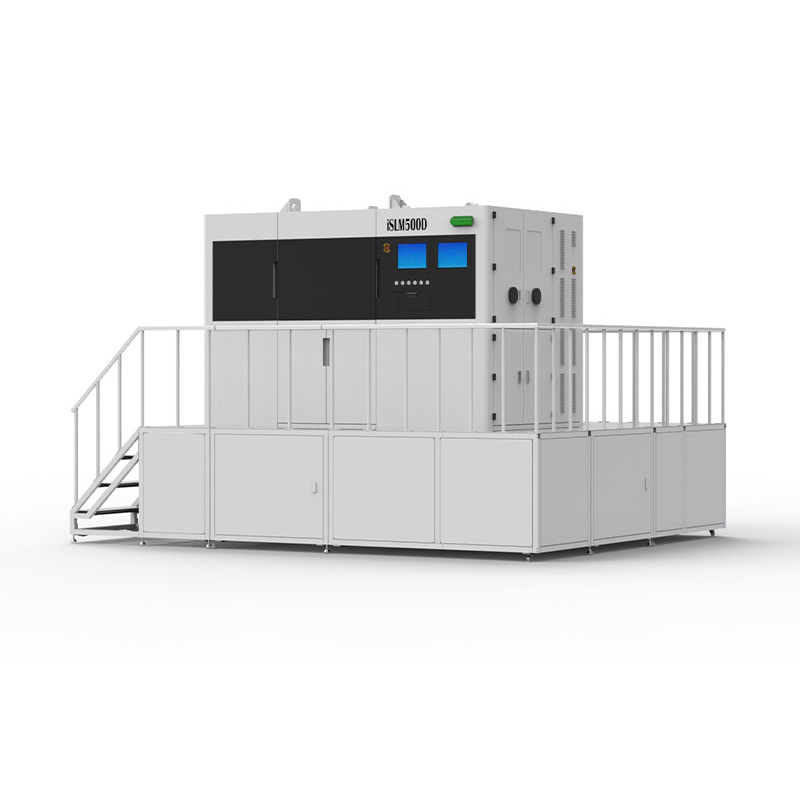

| INSTALLATION CONDITION | Power:380V(±10%) AC 50/60Hz, three-phase, 3/15A Ambient Temperature:20-26ºC Relative Humidity:Less than 40%, non-condensing Size:3.05m(W)×1.90m(D)×3.80m(H) Weight:Approx. 8500kg(Climbing platform not included) |

| WARRANTY | Laser:5000 hours or 12 months (whichever comes first) Main Machine:12 months from installation date |